Self - Tightening Sealing Wedge Gate Valve , High Pressure Gate Valve For Power Station

- Availability: In Stock

- Product Model: Z61W

ANSI Pressure Seal Self-tightening Sealing High Pressure Wedge Gate Valve For Power Station

Pressure Seal Valves

Pressure seal construction is adopted for Valves for high pressure service, typically in excess of above 170 bars. The unique feature about the pressure seal Bonnet is that the body-Bonnet joints seals improves as the internal pressure in the Valve increases, compared to other constructions where the increase in internal pressure tends to create leaks in the body-Bonnet joint.

Specification for Cast Steel Pressure Seal Gate valves

- Size Range: 2" thru 24"

- Pressure Class: 600-4500

- Style: Flexible Wedge and Parallel Slide design

- Materials: A216 WCB, WC6, WC9, C5, C12, C12A, CF8M and special alloys

Design Features and Benefits

- Aluminum bronze yoke sleeve minimize the operating torque.

- T-head stems allows wedge to self-align, eliminating the stem jamming the wedge

- Unique pressure seal design provides the maximum bonnet seal.

- Hardfaced sea rings are welded to body. Tapered design provides unobstructed flow path.

- Streamlined flow path minimizes pressure drop.

- Integral back seat for maximum life.

Bolted Bonnets vs. Pressure Seals

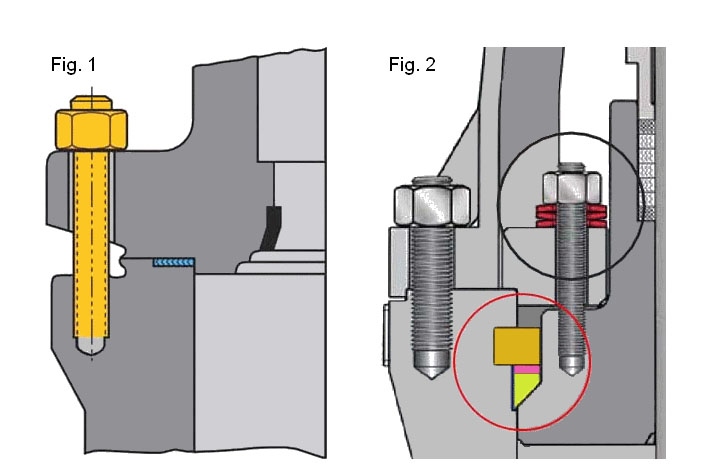

The following FIG. 1 depicts the typical Bolted Bonnet valve. The body flange and Bonnet flange are joined by studs and nuts, with a gasket of suitable design/material inserted between the flange faces to facilitate sealing. Studs/nuts/bolts are tightened to prescribed torques in a pattern defined by the manufacturer to affect optimal sealing. However, as system pressure increases, the potential for leakage through the body/Bonnet joint also increases.

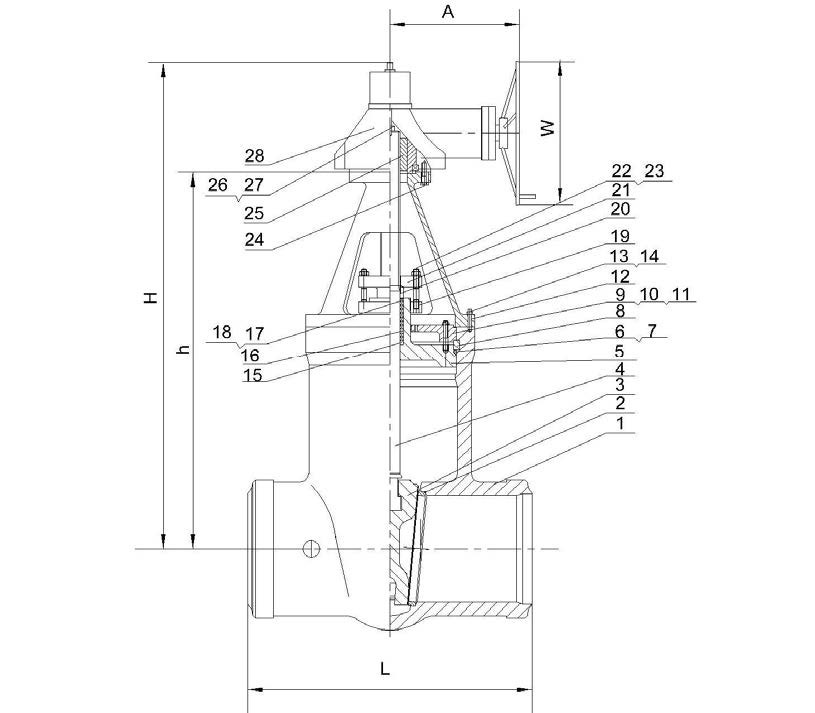

The following FIG. 2 Note the differences in the respective body/Bonnet joint configurations. Most pressure seal designs incorporate "Bonnet take-up bolts" to pull the Bonnet up and seal against the pressure seal gasket. This in turn creates a seal between the gasket and the inner dia (I.D.) of the valve body.