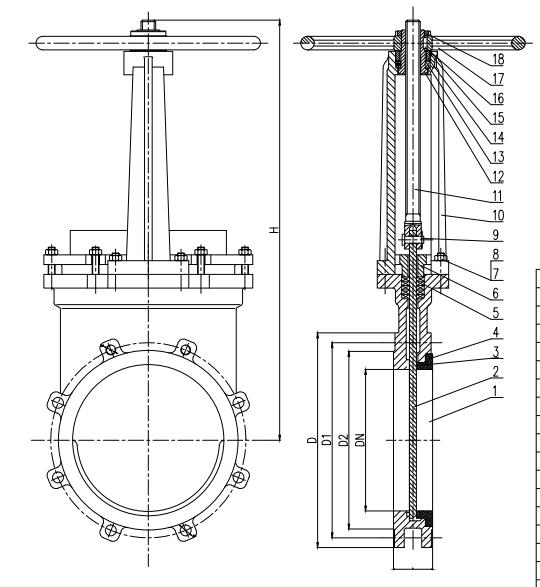

Polyurethane PU Seated Bi Directional Knife Gate Valve

- Availability: In Stock

- Product Model: PZ73U

Pneumatic Actuated Polyurethane PU Seated Bi Directional Knife Gate Valve

TEKO Urethane Lined Knife Gate Valves are designed for on-off applications of abrasive slurry and dry abrasive materials. Flanged Urethane Lined Knife Gate Valves are 100% port area and are ideally suited for applications in mining, chemical and food industries. Flanged PU Lined Knife Gate Valves are available in sizes 2-48" (50-1200mm), and grooved end valves are available in sizes 2-12" (50-300mm). Temperature ratings range from -29 to 80º C as standard. The Carbon Steel body is available with a variety of urethane liner compounds suitable for water, oil, food grade, phosphoric acid, and petroleum.

Our PU Lind Knife valves feature a one-piece, cast-in-place bonded liner that provides bi-directional, drip-tight shutoff to either 150 or 250 psi (1030 or 1720 kPa) CWP. Urethane Lined Knife Gate Valves can also provide bi-directional dead-end service to the full pressure rating of the valve. All wetted surfaces are lined with urethane.

The urethane liner is bonded in place to form a continuous liner throughout the entire body, chest, packing chamber and flange face area. The bonding process enhances the mechanical and abrasion resistance properties of the urethane, which creates a robust seat seal in harsh slurry services. The seamless bonded urethane liner extends over the flange face to serve as the valve's flange gasket.

Specifications

| MAJOR MARKETS | Mining, Chemical and Food industries |

| SIZE RANGE | 2-48" (50-1200mm) |

| TEMPERATURE RANGE | -29 to 80°C |

| PRESSURE RATING | 150 or 250 psi (1030 or 1720 kPa) CWP |

| BODY MATERIAL | Caron Steel with gates of 304, 316, 317, 254 stainless steel or Hastelloy C |

Features

- True bi-directional flow and shut-off, allowing it to be installed in either direction.

- Unique one-piece, precision molded high strength polyurethane liner protects the wetted parts, from corrosion and abrasion. It is field replaceable in all sizes, no need to return to factory for repair.

- The liner has integral flange seals eliminating the need for flange gaskets in most cases.

- The liner has integral sealing beads to support and wipe slurry from the gate, minimizing deflection and improving packing life.

- Testing as per MSS SP-81

- Fully rated 316 stainless steel gate, with optional 17-4 ph to provide improved abrasion resistance against the rigors of abrasive applications.

- Full round port and seat design offers low pressure drop across valve and longer service life in abrasive applications.

- Designed to be a repairable asset, lower the cost of ownership.

- Inverted self-aligning gland box allows for easier setup and longer packing life.

- Complies with MSS SP-81 face-to-face dimensions.

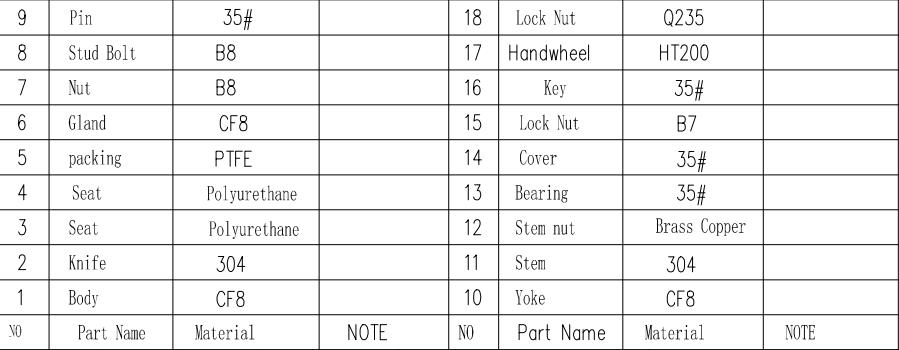

Material List