RPTFE Triple Eccentric API 609 High Performance Butterfly Valves

- Availability: In Stock

- Product Model: D343H

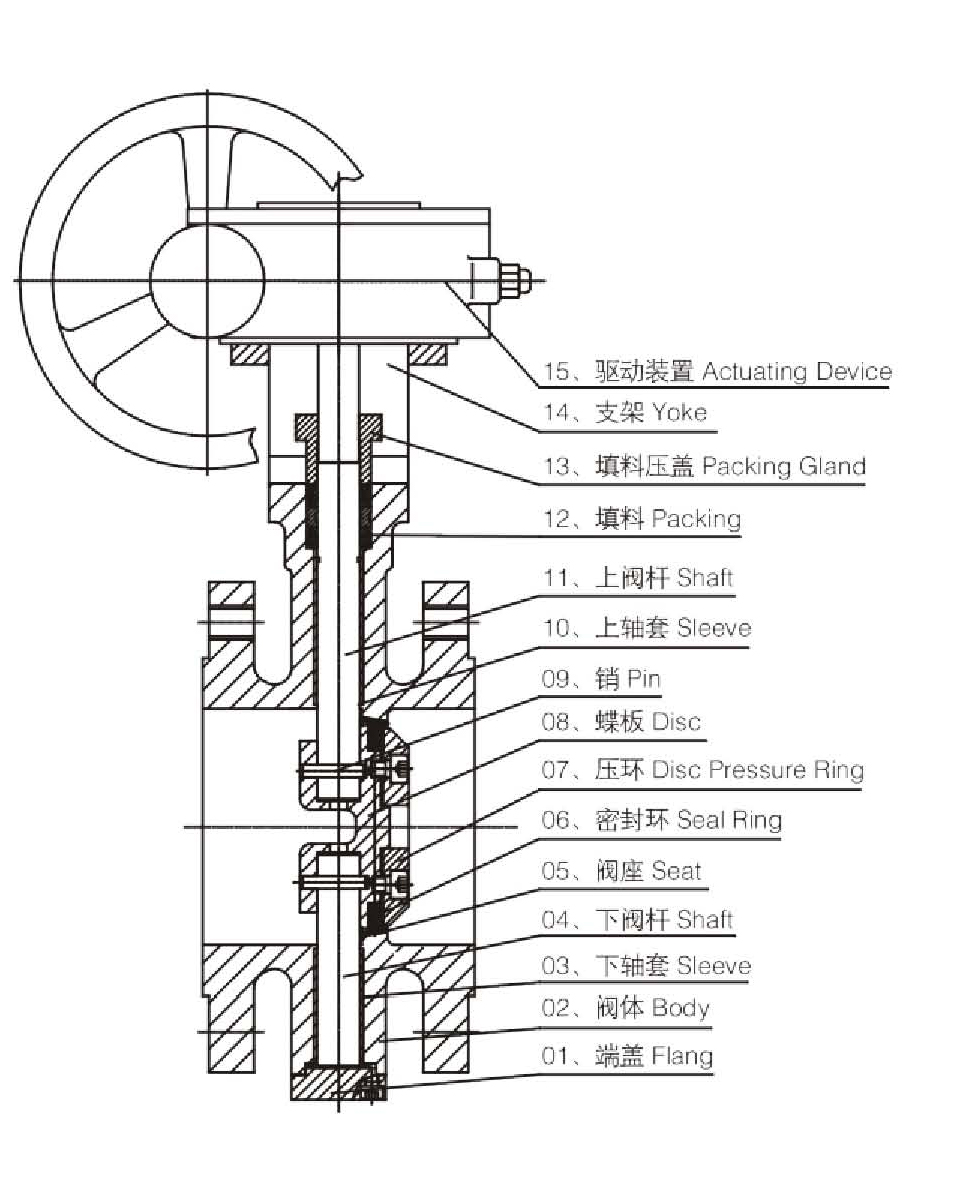

Replaceable Seat Long Life Span Triple Excentric High Performance Butterfly Valve

Applicable Standards

Design & Manufacture: JB/T 8527, API609, ASME B16.3

End Connection: GB/T 12221, API609, ASME B16.46

Face to face: API609

Test & Inspection: API 598, ISO 5208

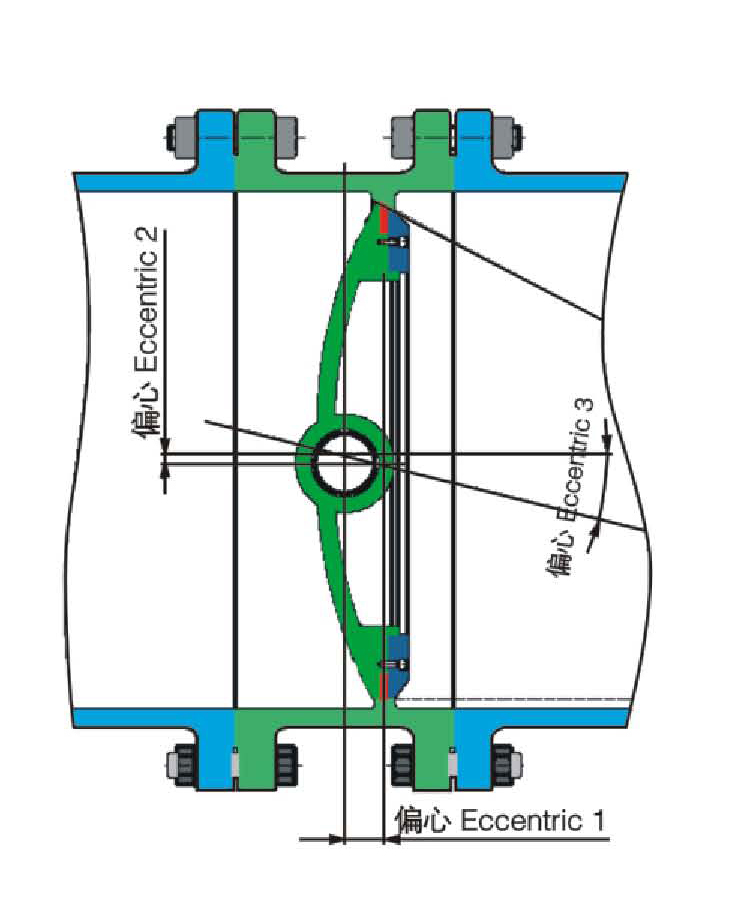

What is Three eccentric design?

Eccentric 1: The centerline of rotation axis/stem and seat deviate from each other for a certain distance to ensure the integrity of the sealing surface;

Eccentric 2: The centerline of rotation axis/stem and body deviate from each other for a certain distance to reduce the friction between the sealing components when open and close the valve.

Eccentric 3: The centerline of valve body and conical seat sealing face deviate from each other for a certain angle to ensure the sealing ring of the disc can be separated or touched with seat rapidly so that friction and squeeze will not exist between the sealing components.

Main Features

The three-eccentric structure, that means an angular eccentric is add to the regular double-eccentric butterfly valve. The third eccentric design make the seal face released as soon as the valve open or close. There is no friction between the seal face and extend the life span largely.

With particular design, the butterfly valves can reach dynamic balance between the inlet/outlet pressure and this reduce the torque comparing to the standard butterfly valve design.

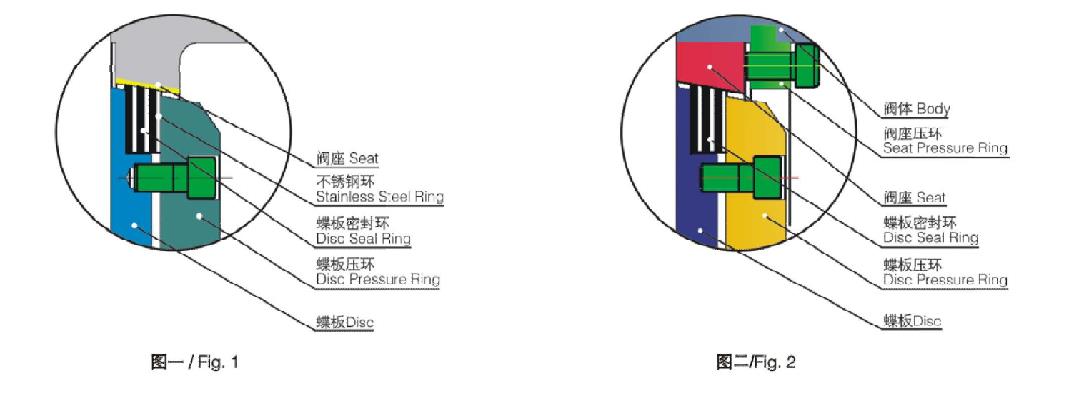

Laminated seal ring is made of laminated layers of metal and non-metal. The dual-sealing structure makes the valve more reliable sealed and the seal’s leaking level up to ANSI B16.104 VI class or ISO5208 A class.

Replaceable seat/sealing (Fig.2) design makes valve easily maintained on field.

Different body seal/disc seal material to meet the working conditions.