High Pressure Eccentric Butterfly Valve , Worm Gear Operation Wafer Butterfly Valve

- Availability: In Stock

- Product Model: D372H

CL900 High Pressure Worm Gear Operation Two Eccentric Butterfly Valve For Power Plant

Product Review

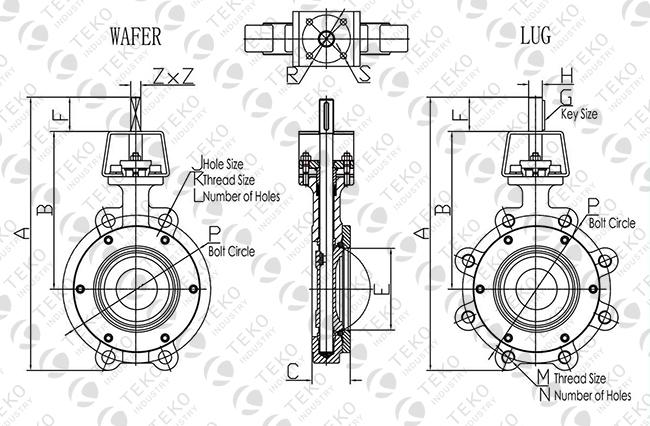

TKEO’s butterfly valve provide an economical solution to flow control with the bi-directional seal service. The major feature is low torque, no wearing, exchangeable seat, easy maintenance. Both wafer and lug body are offered for options.

Production Specifications

| Series | High Performance |

| Brand Name | TEKO |

| Item | Manual Butterfly Valve |

| Type | Wafer/Lug |

| Series | High Performance, Tow offset |

| Nominal Size | 2-60 in |

| End Style | Flanged |

| Pressure Class | ANSI Class 150-900 |

| Pressure Rating | 362-2175 psig |

| Media | Saturated Steam |

| Body Material | Carbon Steel |

| Material Specifications | ASTM A216 Grade WCB |

| Disc Material | 316 Stainless steel |

| Stem Material | 17-4 PH Stainless Steel |

| Seat Material | RPTFE |

| Softgoods Material | PTFE Stem Seal |

| Operator Type | Gear Handle |

| Temperature Rating | 230 degC Seat |

| Standard/Approvals | ANSI B16.5 |

| Application | Chemical and Petrochemical, Power Generation Plants, Ship Building Industries, Fiber Industries, Food Industries, Desalination Industries and Oil Refinery Industries |

Features

Low torque, double eccentric disc makes it leave the seat as soon as the valve opens, minimize the friction and lower the torque. The cost is very competitive when using actuated such as pneumatic and Electric actuators.

Unique seat design, the sea t is 100% exchangeable for all the valve of same size and seal type, no need to change the body or other components. Removable seat retainer is the only step to replace a new sea ring, unnecessary to disassemble the disc and stem.

As the above features, it is very easy to maintenance and comparing to total cost, it is very cost efficiency.

With double seat design, it is strictly in accordance with API 607 specification. Bi-directional soft seal design for zero-leakage in normal operation and a metal-to-metal seal after fire