TFM1600 Seat High Pressure Flange End Ball Valve For Oil & Gas API 6D

- Availability: In Stock

- Product Model: Q47F

TFM1600 Seat High Pressure Flange End Ball Valve For Oil & Gas

1. APPLICATIONS

Chemical, Petrochemical, Oil Refinery, Gas,Power Plant, General Industry etc.

2. FEATURES

* Design - API 608/ API 6D/ BS5351/ ANSI B16.34/ ISO 14313/ MSS SP 72

* Face to Face - ASME B16.10/ ISO5752

* Flanged Ends - ASME B16.5/ ASME B16.47/ ISO7005-1/ API 605/ BS 3293/ DIN

* Butt-Weld Ends - ASME B 16.25

* Fire Safe - API 607/ API 6FA

* Test - API 598/ API 6D

* Seat - PTFE, RTFE, Graphite, Metal to Metal

* Bore - Full & Reduced Bore

* Fabrication - One Piece/Two Piece/Three Piece Body

3. MATERIALS

* Cast Steel

ASTM A216 WCB, WCC

ASTM A217 WC9

ASTM A351 CF8, CF8M, CF3, CF3M, CF3MN,CN7M

ASTM A352 LCB

SUL 904L

* Forged Steel

ASTM A105, A105N

A182 F304, F304L, F316, F316L, F51, F11, F22

4. PRESSURE RATING & SIZE

* API, ANSI, ASME, MSS, BS, DIN, JIS

* 150#~2500# : 2"~32"

PN6~PN250 : DN50~DN800

JIS 10K~40K : 50mm~1400mm

5. OPERATORS & OPTION

* Pneumatic Cylinder/ Motor/ Gear/ Chain Wheel/Anti-Static/ Locking Device/ Limit Switch/ Lever etc.

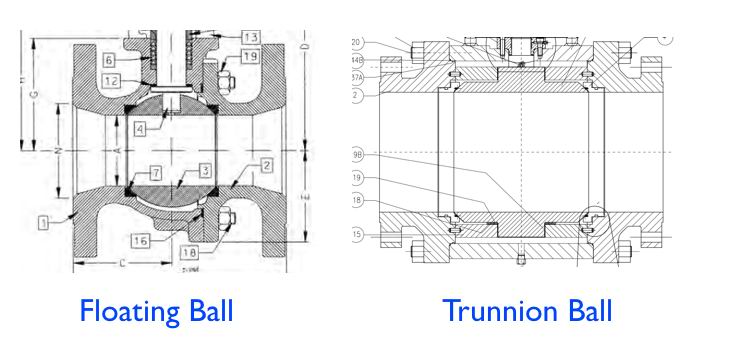

6. TRUNNION BALL STRUCTURE

As described above, there comes a point where owing to the high value of the loading forces on the ball it becomes no longer possible for the seats to support the ball and an alternative design is required.

The trunnion mounted ball design in effect addresses this problem where in effect the shaft, ball, and trunnion act as single assembly that supports the ball instead of the seats and the seats become “floating” in a kind of reversal of the “floating ball” design. Similarly, trunnion mounted ball design is also capable of bi-directional sealing.

An advantage of trunnion ball design over floating ball is the lower operating torque of the ball. This is particularly advantageous when the ball valve is actuated because it reduce the size of the actuator and hence the overall costs of the valve actuation package. Obviously this difference becomes important when the pressure class and valve increases.