High Durable Air Operated Slurry Pinch Valve Full Bore NR hose For Bulk Material

- Availability: In Stock

- Product Model: GJ41X

Full Bore NR hose High Durable Slurry Air Operated Pinch Valve For Bulk Material

Description

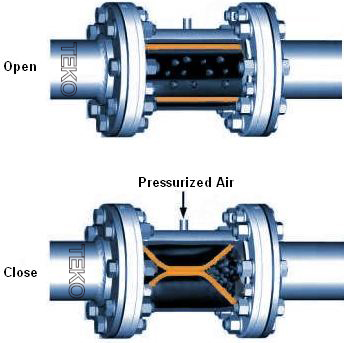

The TEKO air operated pinch valve can handle Bulk materials in powder, pellet, flake or granular form in pneumatic conveying system. A pinch valve functions as a shut-off valve and prevents the product flow completely with the aid of proper sealing. Actuation of the valve, the pinching action is accomplished by air pressure applied on the sleeve. The flexible sleeve tightly closes the line with the help of actuation pressure. When the pinch valve is in open position, bulk material flows freely through the full bore of the valve. Since there is no change in cross sectional area through the pinch valve, pressure drop is kept minimum.

Material List

| Body | Carbon steel, cast iron Aluminum, Plastic |

| Match flange | Carbon Steel |

| Sleeve Material | Natural Rubber, NBR, EPDM, etc |

Design Features and Benefits of Flexible Pinch Valves

Low profile pinch valve body design maintains a minumum flange-to-flange length to minimize space requirements. It adapts easily to new installations and retrofits. Uninterrupted bulk material flow when the pinch valve is open due to smooth internal geometry with no lodgement points. No pressure loss during product flow. Pinch valve can be actuated while material is being discharged in gravity flow line. Easy to replace flexible sleeve. Heavy duty flexible sleeve ensures long years of reliable operation

Pinch Valve Application Examples

Pinch valves are widely used in bulk material storage silos that are filled by bulk tanker trucks. They are installed at the inlet of silo filling pipeline to control product flow from bulk truck to silo. When installed on the pneumatic conveying lines, pinch valves are used to allow or prevent product flow in determined pipeline routes.